Page 116 - 《橡塑技术与装备》2025年10期

P. 116

橡塑技术与装备

HINA R&P TECHNOLOGY AND EQUIPMENT

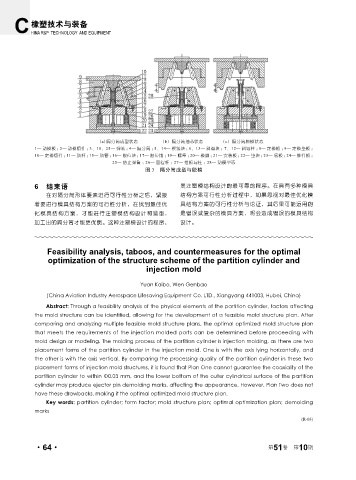

(a) 隔分筒成型状态 (b)隔分筒抽芯状态 (c)隔分筒脱模状态

1— 动模板 ; 2— 动模镶件 ; 3、18、25— 弹簧 ; 4— 隔分筒 ; 5、14— 楔紧块 ; 6、13— 斜滑块 ; 7、12— 斜导柱 ; 8— 定模板 ; 9— 定模垫板 ;

10— 定模镶件 ; 11— 顶杆 ; 15— 顶管 ; 16— 限位块 ; 17— 限位销 ; 19— 螺塞 ; 20— 模脚 ; 21— 安装板 ; 22— 垫块 ; 23— 底板 ; 24— 推件板 ;

25— 防止弹簧 ; 26— 回程杆 ; 27— 推板导柱 ; 28— 动模型芯

图 3 隔分筒成型与脱模

6 结束语 是注塑模结构设计的最可靠的程序。在具有多种模具

在对隔分筒形体要素进行可行性分析之后,紧接 结构方案可行性分析过程中,如果忽视对最佳优化模

着要进行模具结构方案的可行性分析,在找到最佳优 具结构方案的可行性分析与论证,其后果可能运用的

化模具结构方案,才能进行注塑模结构设计和造型, 是错误或复杂的模具方案,将会造成错误的模具结构

加工出的隔分筒才能更优质。这种注塑模设计的程序, 设计。

Feasibility analysis, taboos, and countermeasures for the optimal

optimization of the structure scheme of the partition cylinder and

injection mold

Yuan Kaibo, Wen Genbao

(China Aviation Industry Aerospace Lifesaving Equipment Co. LTD., Xiangyang 441003, Hubei, China)

Abstract: Through a feasibility analysis of the physical elements of the partition cylinder, factors affecting

the mold structure can be identified, allowing for the development of a feasible mold structure plan. After

comparing and analyzing multiple feasible mold structure plans, the optimal optimized mold structure plan

that meets the requirements of the injection molded parts can be determined before proceeding with

mold design or modeling. The molding process of the partition cylinder is injection molding, as there are two

placement forms of the partition cylinder in the injection mold. One is with the axis lying horizontally, and

the other is with the axis vertical. By comparing the processing quality of the partition cylinder in these two

placement forms of injection mold structures, it is found that Plan One cannot guarantee the coaxiality of the

partition cylinder to within Φ0.03 mm, and the lower bottom of the outer cylindrical surface of the partition

cylinder may produce ejector pin demolding marks, affecting the appearance. However, Plan Two does not

have these drawbacks, making it the optimal optimized mold structure plan.

Key words: partition cylinder; form factor; mold structure plan; optimal optimization plan; demolding

marks

(R-03)

·64· 第 51 卷 第 10 期